Powerplant O&M Services

PowerServ in cooperation with Thomassen Energy, MFS and various other solution provider companies from Europe and US, is in an excellent position to provide that kind of innovation.

We offer owners of GE-type Heavy duty and Aero-derivative gas turbine systems worldwide a full package of products and services, which increase performance & reliability, minimize costs & risks, optimize operations & maintenance and reduce emission values.

GE HEAVY DUTY GAS TURBINES

Our business partner Thomassen Energy is the single source solution provider for GE Heavy Duty Gas Turbine after sale services.

With its service centers, located in the Netherlands, Italy, and United Arab Emirates we are able to provide after sales services all over the world.

Experience areas are:

Field Service, Repair, Spare Parts, Conversions, Modifications and Upgrades, Training, Flexible Service Agreements, Gas Turbine Remanufacturing and Gas Turbine Relocation

GE AERODERIVATIVE GAS TURBINES

Our business partner Mechanical Field Support B.V. is a Dutch (independent) company offering all parts and services for commercial aeroderivative engines and packages.

MFS B.V. consists of a highly skilled team of experts with many years of experience offering the best possible service. Our customers are located all over the world, including offshore installations, commercial marine propulsion and power generation plants.

MFS is well experienced in providing:

- Improvement in profitability in maintenance

- Reduction in downtime

- Decrease in total cost of ownership by supplying gasturbines spare parts, shop maintenance, field service, instrumentation and controls, consult and trainings

MFS staff are specialized in repairing and maintaining GE aeroderivative gas turbines. In addition to offering a wide range of high quality spare parts for the GE aeroderivative gas turbines, including LM1600, LM2500, LM5000 and LM6000. All these parts and services are offered at competitive rates.

STEAM TURBINES

The evolution of the power market has changed the structure of the electricity value chain which is now involving and heavily dependent upon several new factors such as efficiency constraints, production targets, operational flexibility, volatile fuel costs, competitive electricity prices and increasing environmental concern. Under these demanding conditions, PowerServ can provide after sale services for all types of steam turbines, complying with recent developments in the sector.

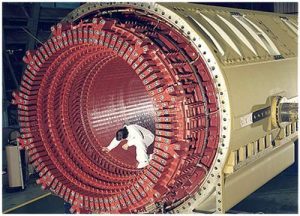

GENERATORS

PowerServ can offer a full range of services and qualified personnel for erection and/or supervision, startup and testing of Turbogenerators. The availability of standard arrangements, and in some cases packaged solutions, ensures rapid, problem-free erection and startup.

Throughout our global business partners we are able to provide worldwide technical assistance in the fields of maintenance, spare part supply and preventive maintenance programs, ensuring that customers are in the best position to achieve optimum operation.

Our comprehensive and reliable after-sales services are regularly reviewed to assimilate operating experience.

Diagnostic tools are available to monitor turbogenerator parameters and behavior continuously, in order to detect ageing trends and address maintenance activities.

Moreover, thanks to Reverse Engineering capabilities, we can offer complete maintenance, restoration and modification of non-proprietary, third party turbogenerators.

POWER PLANT & HRSG INSPECTIONS

Our business partner Tetra Engineering was founded by three engineers in 1989. Their previous experience was working together on improving the performance and reliability of nuclear and large fossil-fired power plants.

They continued this activity during the first years at Tetra. Starting in the late 90’s they began focusing their efforts on providing services to the rapidly expanding installed base of HRSGs. This made Tetra one of the first companies outside of the OEMs to provide full-scope inspection and specialized engineering support services for this type of boiler.

Our home office is located in Simsbury, Connecticut USA; a European office was opened in Sophia Antipolis, France in 1991. This was joined by an office in Dubai in 2014.

Today the three founding principals are still actively working at Tetra; they have been joined by a multinational and multilingual staff to serve the global power generation market.

EXCITATION SYSTEMS & DRIVES

Our business partner Nidec ASI is one of the world’s leading suppliers of the complete electrical package which includes electric power and control systems, electric motors and generators, LV and MV drives and a precise Power Supply and Power Quality components. Each solution is tailored to client life cycle requirements and guarantees performance, reliability and safety.

SPARE PARTS

Roper Pump is dedicated to the highest standards in the manufacture and aftermarket support of liquid fuel pumps and flow dividers for industrial frame type gas turbines in the power generation, oil & gas, pipeline, refinery and petrochemical industries.Since the 1950’s, Roper Pump’s pioneering efforts in the design of flow dividers, as well as high pressure pumps, have now become an industry standard for heavy duty gas turbine multi chamber combustion systems that require the precise delivery of fuel into each combustion can.

Today, our solution driven engineers continue to develop new and patented products tailored to specific applications. The latest technological advances are also applied to our existing equipment through upgrades and product improvements with the objective to withstand the stringent conditions encountered in the field. Roper fuel pumps and flow dividers are installed worldwide in virtually thousands of gas turbines manufactured by all major turbine OEMs.

Jansen’s Aircraft Systems Controls (JASC) was founded in 1990 by late Harvey Jansen, who has over 50 years of engineering experience in fluid control systems. JASC provides practical engineering solutions for the aerospace, space and gas turbine industries as well as providing installation services for power generation operators.

JASC is headquartered in Tempe, Arizona, a suburb of Phoenix, and is located within a 10 minute drive of Sky Harbor International Airport and within a 20-mile radius of its major outside suppliers. This makes JASC conveniently accessible for out-of-town visitations and the close location of our supplier base simplifies the logistics of product development and production.

JASC implements a management philosophy that involves total participation by all employees. This employee involvement creates a very cooperative environment that is conducive to high-quality and on-time product shipments to the customer. JASC is ISO 9001:2008 and AS9100B certified.